What role does silicon play in metal alloys?

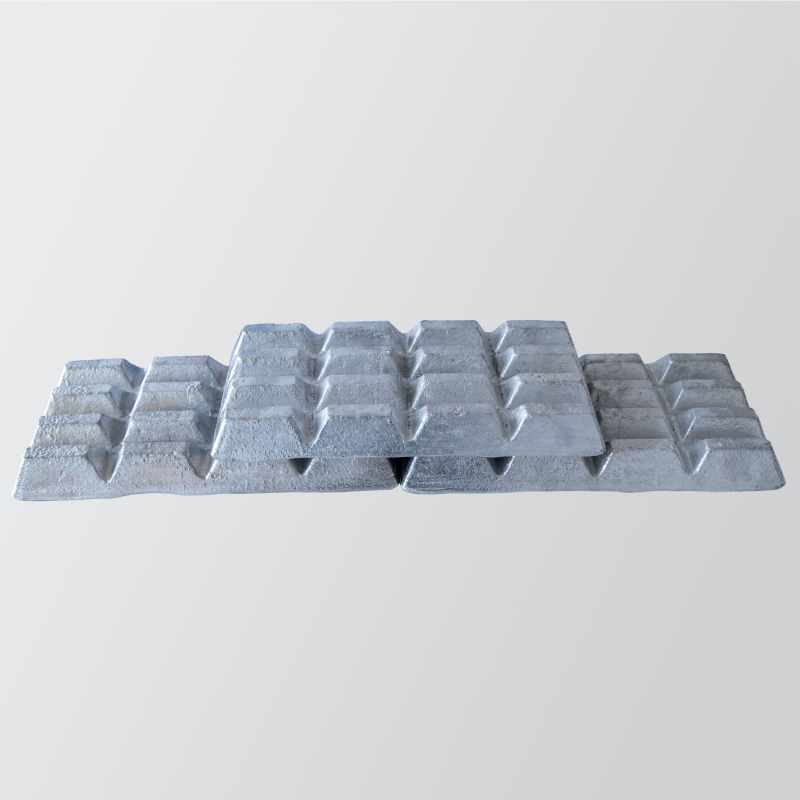

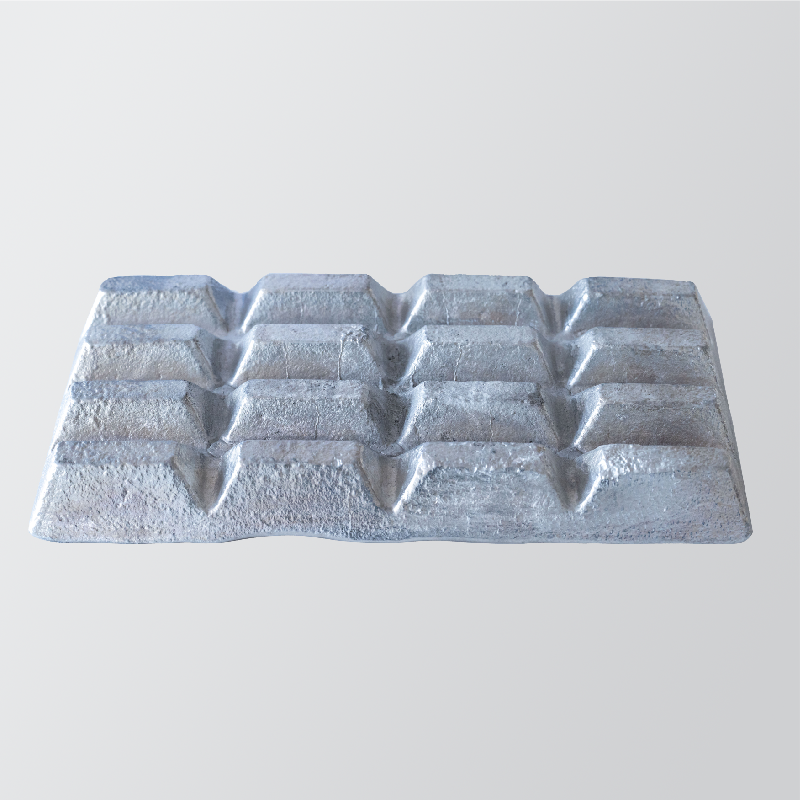

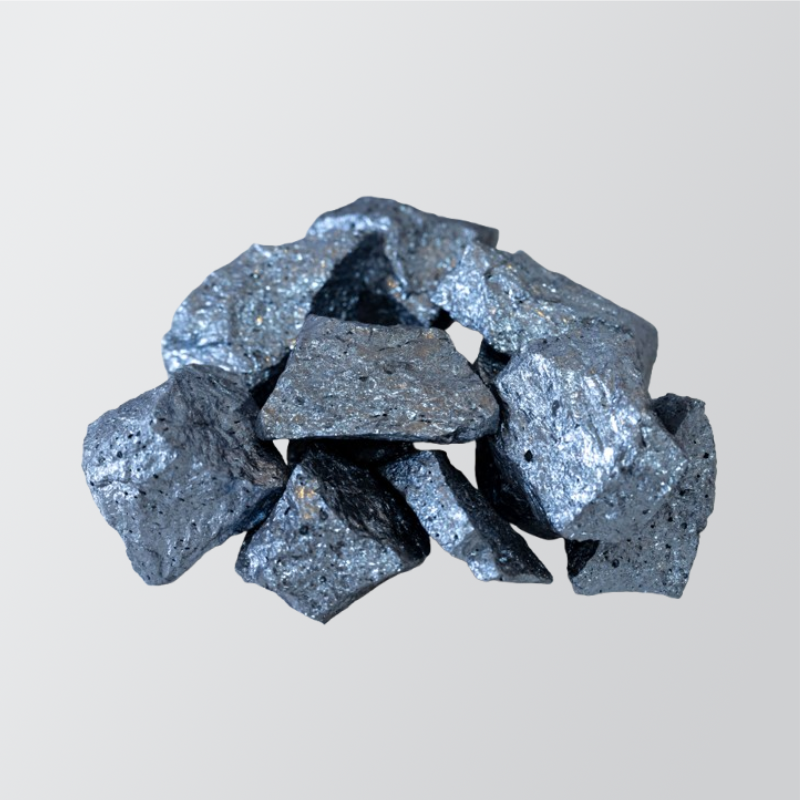

Silicon is crucial in metal alloys, particularly in aluminum alloys from brands like ProsperLoong Aluminum. It improves the alloy's fluidity and reduces its melting point, enhancing casting processes. Silicon in aluminum alloys, such as those from ProsperLoong, typically ranges from 4% to 13% by weight, optimizing strength and ductility. This is particularly valuable in products like automotive components where precise castability is vital.

In comparison, other brands like Alcoa (www.alcoa.com) might use varying silicon concentrations to achieve specific properties. For instance, a 12% silicon content can significantly increase wear resistance, ideal for high-stress applications. Silicon also contributes to corrosion resistance, making it essential for outdoor applications where longevity is critical.

Therefore, the role of silicon in metal alloys is foundational to achieving desirable mechanical and physical properties, which ProsperLoong Aluminum capitalizes on to deliver high-quality solutions to its clients.

User Hot Search:degassing refining agent, si metals, silicon metal, carborundum silicon carbide.