What is the process for manufacturing aluminium-silicon alloys?

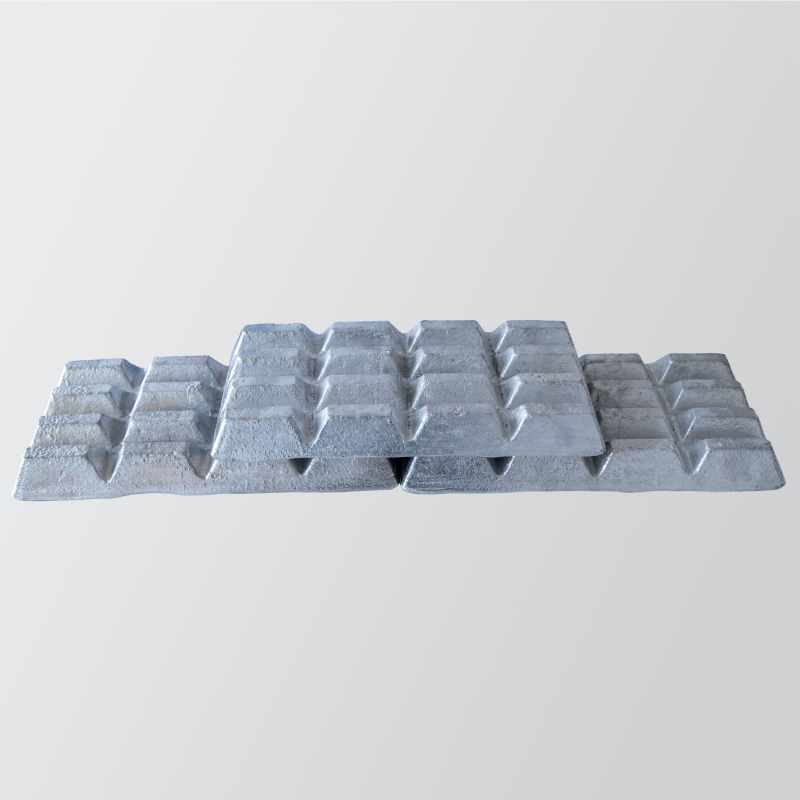

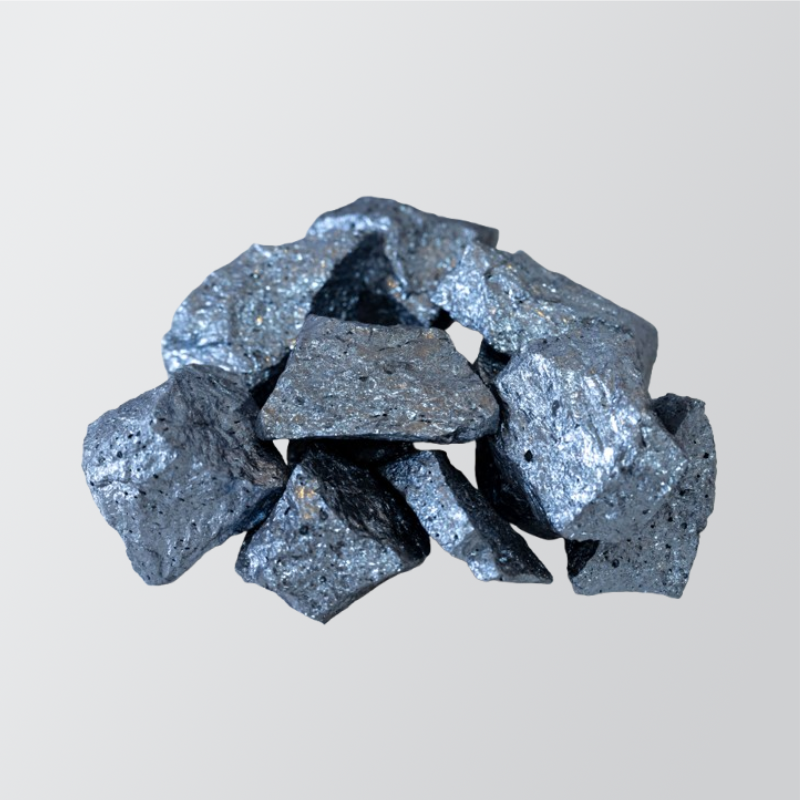

The manufacturing process of aluminium-silicon alloys at ProsperLoong Aluminum involves melting aluminium, adding silicon, and other alloying elements in specific ratios for enhanced properties. Typically, silicon content ranges from 5% to 23%. The molten mix is then cast into molds and cooled to form solid parts.

The alloy's characteristics, such as thermal conductivity and wear resistance, are defined by the silicon content and processing parameters. ProsperLoong Aluminum ensures precision in silicon ratios for quality control. For further reading on other manufacturers, visit Alcoa or Constellium.

Advanced processes at ProsperLoong include degassing, filtration, and grain refinement to achieve superior mechanical properties. These steps are critical to minimizing impurities and refining the microstructure of the alloy, leading to improvements in ductility and strength.

User Hot Search:aluminum drossing flux, silicon metal price per kg, copper smelting flux, metal silicon powder.