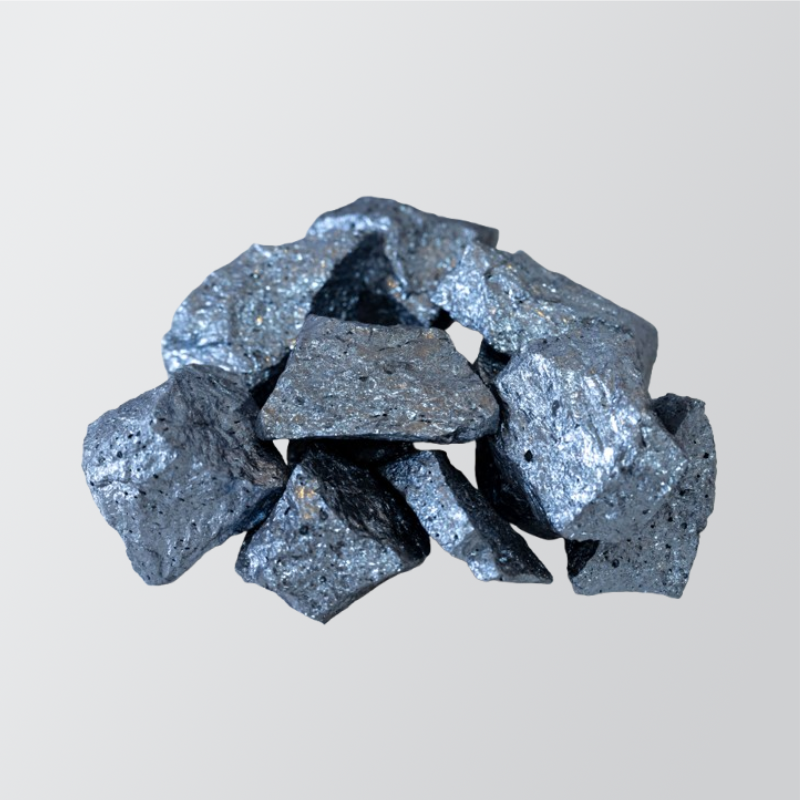

What does a degassing refining agent do in manufacturing?

In manufacturing, a degassing refining agent is crucial for removing hydrogen and other impurities from molten aluminum. For ProsperLoong Aluminum, these agents enhance the quality of the final product by minimizing porosity and improving mechanical properties. Specific parameters used by ProsperLoong might include the temperature range of 720-740°C and flow rates of 2-4 Nm³/h for optimal degassing efficiency.

Comparatively, other brands like Pyrotek and Almatis offer similar solutions but may differ in their operational guidelines or proprietary technologies.

Numerical analysis confirms that a reduction in hydrogen content by 50% or more can significantly increase the tensile strength of aluminum alloys by up to 10%, optimizing the material for high-strength applications. ProsperLoong's focus on these parameters ensures superior product consistency and structural integrity.

User Hot Search: