Silicon Metal Enhancers for Aluminum Alloy Casting

Product Functionality

Metallic silicon plays a critical role in steel smelting as an effective deoxidizer, interacting with oxygen to form SiO₂, thus minimizing oxygen content in steel. It serves as an essential alloying component, enhancing the strength, hardness, and elasticity of steel. In cast iron, silicon boosts casting performance and elevates wear and heat resistance of castings.

Casting and Corrosion Benefits

- Improve Casting Performance: During casting, metallic silicon enhances molten metal fluidity and reduces defects.

- Refine Grains: Silicon contributes to fine grain structure, improving the mechanical properties of materials.

- Corrosion Resistance: Silicon augments the corrosion resistance of metals, especially in high-temperature and acidic settings.

Usage Method

Typically added later in the smelting process, metallic silicon ensures effective dissolution. Suitable for electric arc furnaces, converters, or induction furnaces, it can be added in block, granular, or powdered forms. For powdered silicon, use a blowing or wire feeding machine. The addition amount generally ranges from 0.2%-3.0%, adjusted per metal type and process requirements. After addition, thorough stirring ensures even distribution and full reaction.

Main Advantages

- Enhanced Material Properties: Metallic silicon significantly boosts the strength, hardness, and elasticity of steel and improves cast iron's performance and wear resistance.

- Effective Deoxidation: As a deoxidizer, it greatly reduces oxygen content in steel, enhancing quality.

- Cost-Effectiveness: With a relatively low price, metal silicon offers significant improvements in metal performance.

- Environmental Protection: Byproducts like SiO₂ are environmentally harmless.

Packaging and Storage Methods

Packaged in moisture-proof materials such as woven bags or iron barrels lined with plastic, metallic silicon should be stored in dry, well-ventilated spaces to prevent moisture absorption. Avoid storing with corrosive or flammable substances.

Precautions

- Over-addition may affect metal performance; strictly control addition amounts.

- Avoid humid environments to prevent agglomeration.

- Ensure packaging integrity during transport to prevent leakage or moisture exposure.

- Dispose of waste residue per environmental guidelines.

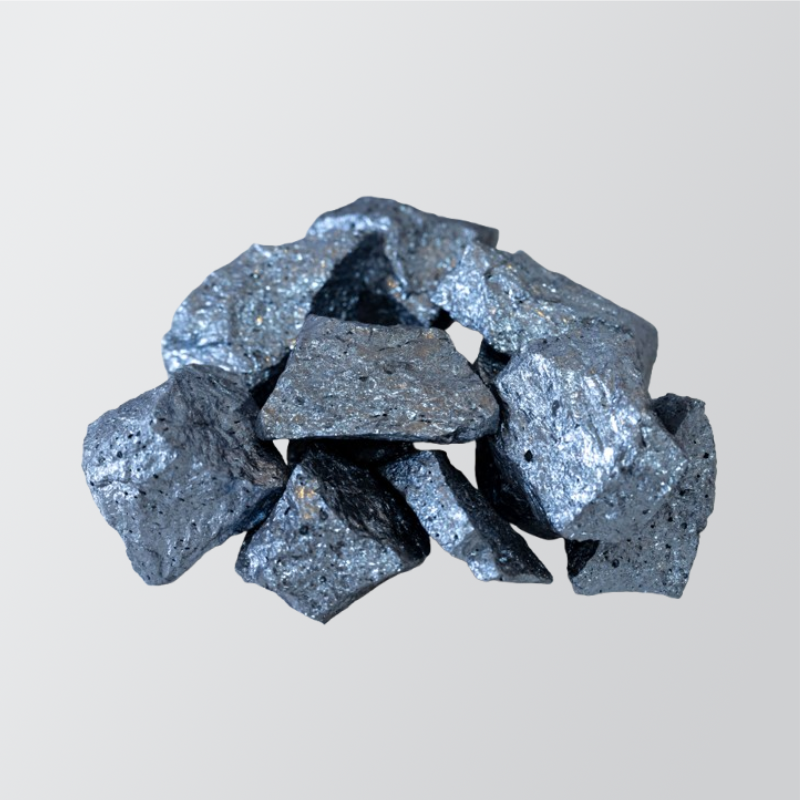

Product Components and Characteristics

- Main Component: Silicon (Si), typically in ferrosilicon (FeSi) or pure form.

- Silicon Content: Ferrosilicon alloys contain 45%-90% silicon, varying by type.

- Other Elements: Trace amounts of iron (Fe), aluminum (Al), calcium (Ca), etc.

- Physical Form: Available in block, granular, or powder form for easy addition.

- Melting Point: Silicon melts at approximately 1414°C, slightly lower in ferrosilicon.

- Density: Silicon's density is about 2.33 g/cm³, slightly higher in ferrosilicon.