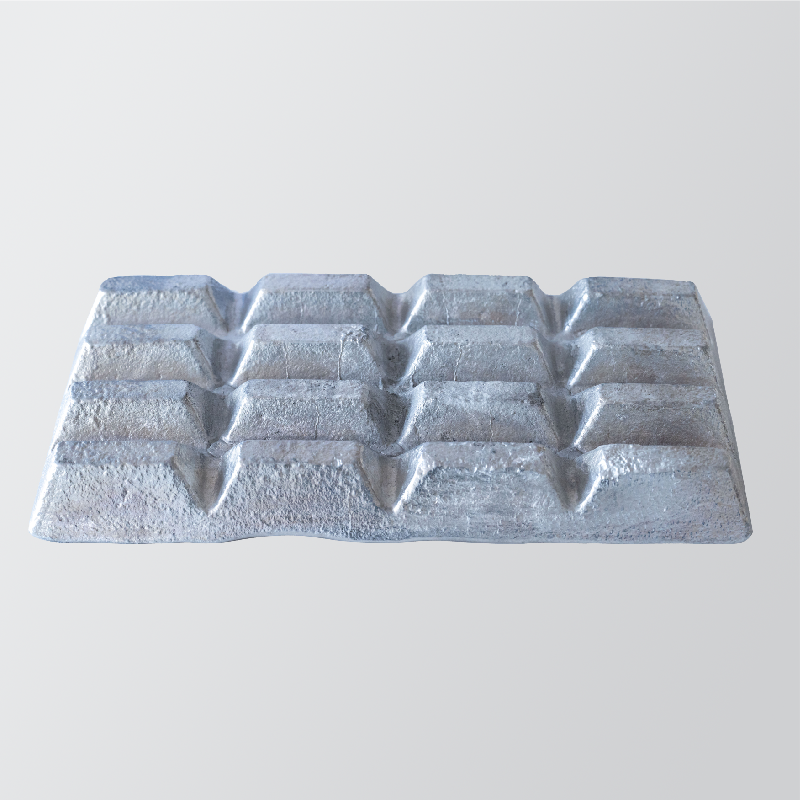

Rare Earth Aluminium Alloys: Strong & Heat Resistant

Product Features

Enhance the performance of your aluminum products with our Aluminum Rare Earth Alloy, featuring mixed rare earth elements such as lanthanum, cerium, praseodymium, and neodymium. These elements refine grains, purify melts, and improve both the strength and plasticity of alloys, leading to superior processing performance.

- Performance Improvement: Rare earth elements refine grains, purify melts, and enhance alloy strength and plasticity.

- Impurity Reduction: Minimize the harmful effects of silicon impurities on electrical properties in electrical aluminum.

- Deterioration and Purification Effect: Optimize the morphology and distribution of silicon, ensuring long-lasting effects that are inheritable through remelting and modification.

Usage and Dosage

Follow these operation steps for optimal results:

- Bake and dry the alloy before use.

- Ensure the adding temperature exceeds 720℃.

- Add 0.03-0.15% rare earth elements to the aluminum liquid, adjusted based on the alloy type and demand. Typically, use 0.3-1.5% relative to the aluminum being treated.

Operation Steps

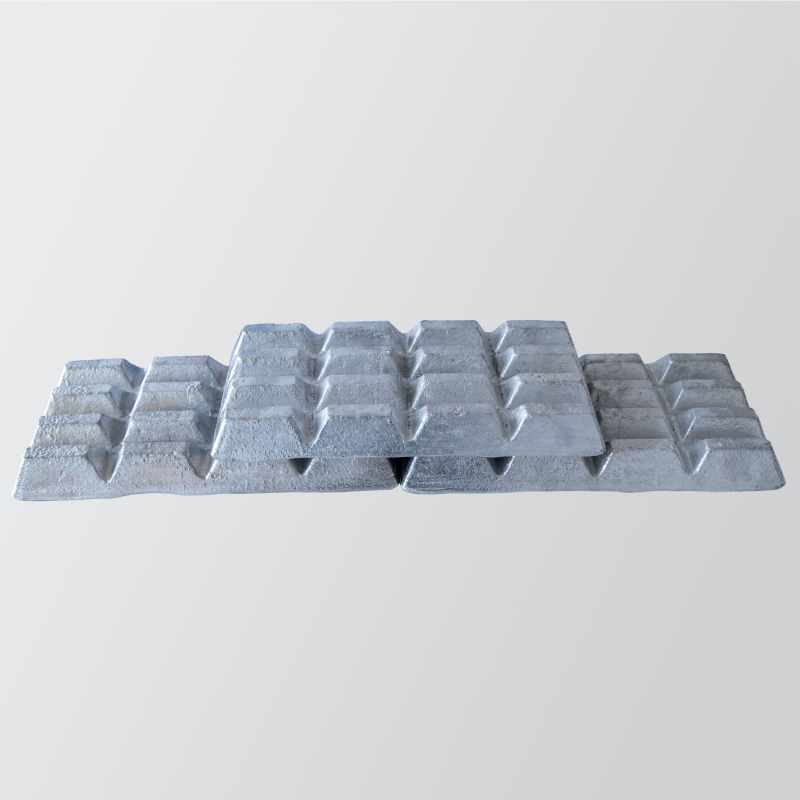

- Place the alloy block into the aluminum liquid and stir evenly after melting.

- Let it stand for over 10 minutes, remove slag, and pour a test rod to inspect the fracture.

- Fracture Inspection: A normal fracture should appear silver-white with a velvety texture, fine and uniform grains, and no silicon bright spots.

Packing and Storage Methods

- Alloys are packaged with materials that prevent contamination and damage during transport and storage.

- Store in a dry, cool place to avoid moisture and deterioration.

Application Scenarios

- Aerospace: Ideal for high-temperature components like aircraft engine turbine blades.

- Automobile Industry: Perfect for manufacturing engine parts to enhance wear resistance, thermal stability, and energy efficiency.

- Chemical Industry: Used in manufacturing chemical equipment and pipelines for its corrosion-resistant properties.

- Electronic Technology: Suitable for electronic components, circuit boards, and connectors, especially in high-frequency electronic devices.

- Oil and Gas Extraction: Used for high-temperature and corrosion-resistant oil drill bits and pipelines.

- Medical Devices: Suitable for medical devices, artificial joints, and dental materials due to biocompatibility and corrosion resistance.

- Optical Devices: Ideal for manufacturing lasers, infrared sensors, and optical communication devices.

Preparation Methods

There are various preparation methods, each offering unique advantages:

- Smelting Method: The most traditional and common, involving melting, adding rare earth elements, stirring, and solidifying.

- Powder Metallurgy Method: Uses powdered raw materials to create a uniform alloy composition with reliable performance.

- Continuous Casting and Rolling Method: A high-efficiency, low-cost method for producing plates and strips.

Environmental Protection and Economic Benefits

Compared to traditional materials like copper bars or galvanized steel, Aluminum Rare Earth Alloys offer significant environmental protection and economic benefits:

- Reduction of zinc and copper heavy metal ion concentration by over 90% after burial.

- Saves 40% in total life cycle investment compared to galvanized steel, 67% compared to pure copper, and 53% compared to copper-clad steel.

Model and Application Range

Model: XL-LXT

Application Range: Suitable for modification treatment of aluminum-silicon alloys with extended casting time, aluminum liquid purification, and rare earth element addition, particularly in the electrical aluminum industry.