Grain Refiner: Al-Boron Alloy for Aluminum Casting

Introduction to Aluminum-Boron Alloy

Aluminum-boron alloy is a master alloy known for its high density and melting point, allowing it to maintain stability and strength in high-temperature environments. With excellent thermal and electrical conductivity, it is ideal for applications requiring superior heat and electricity management. This alloy contains 2.5-3.5% boron and offers several key advantages:

Performance Improvement

- High-melting point AlB2 particles in the aluminum liquid refine grain structure during solidification.

- Enhances strength and plasticity of aluminum materials or castings.

- Improves comprehensive mechanical properties and electrical conductivity.

Optimal Use

- Addition temperature should exceed 700℃ to minimize boron loss.

- Boron content suitable for grain refinement in aluminum alloy smelting ranges from 2.5-3.5%.

Usage and Dosage

- Pre-use: Bake and dry the material.

- Temperature: Ensure above 700℃ for effective use.

- Amount: Generally 0.1-0.5%, adjust based on specific testing.

- Method: Remove scum, gently introduce the alloy into the aluminum liquid, stir well, and let stand for 5-10 minutes.

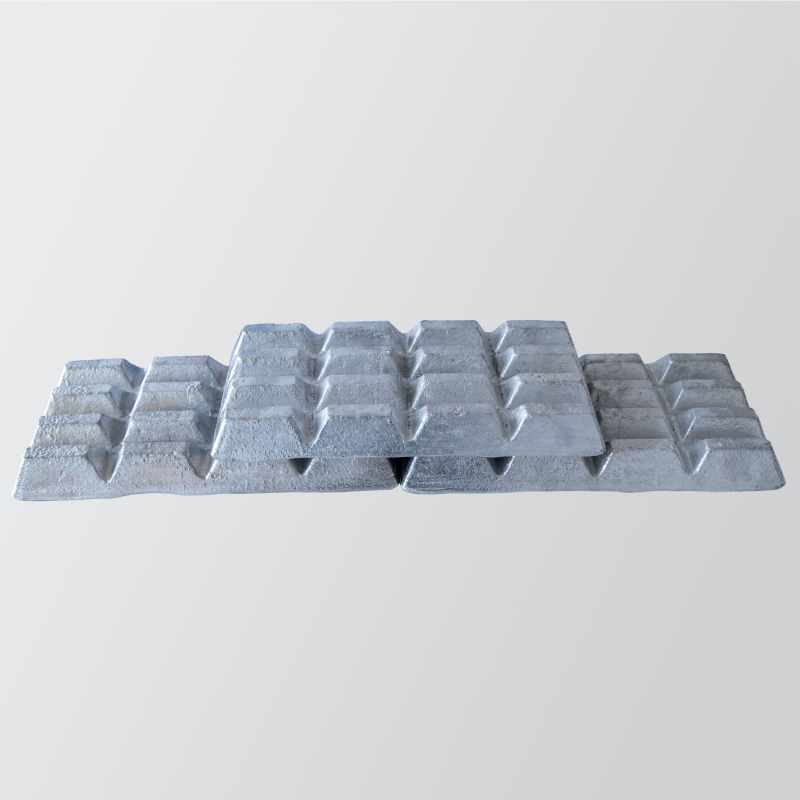

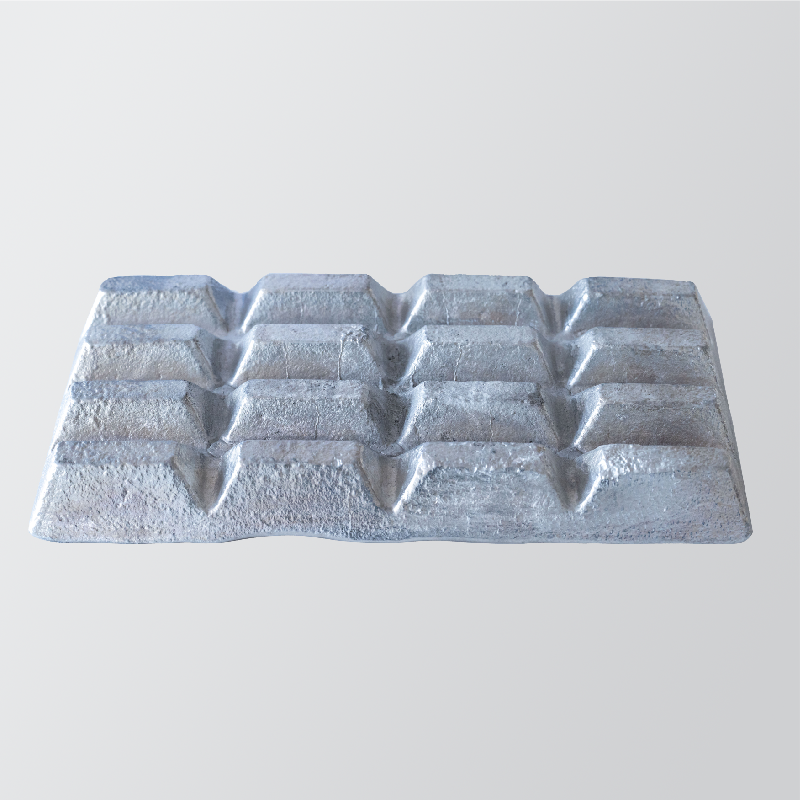

Packaging and Storage

- Form: Blocks with metallic luster, each weighing 250g, packaged in 25±0.25kg boxes.

- Conditions: Store in a ventilated, dry, and moisture-proof environment.

Application Scenarios

Automobile Manufacturing

Demand is high for aluminum-boron alloy in the automotive industry, mainly for lightweight parts like engine blades, brake discs, and pistons. This alloy enhances performance and fuel economy.

Aerospace

Due to its high temperature resistance and strong mechanical properties, aluminum-boron alloy is ideal for aircraft parts, offering reduced weight and improved flight performance.

Construction Engineering

Utilized for lightweight structural and decorative components, aluminum-boron alloys offer weight reduction, enhanced seismic resistance, and durability in buildings.

Electrical and Electronic Fields

Perfect for manufacturing heat sinks and connectors, its thermal conductivity ensures optimal heat dissipation, extending the lifespan of electronic components.

Conclusion

Aluminum-boron alloys are versatile, with extensive applications in automotive, aerospace, construction, and electronics due to their exceptional physical and chemical properties. They serve as effective grain refiners in aluminum alloy casting and melt purification for electrical applications, making them indispensable in high-performance sectors.