AlTiB Alloys for Effective Grain Refinement in Casting

Aluminum-Titanium-Boron Alloy: Usage and Dosage

Gain insights on the effective use of Aluminum-Titanium-Boron alloys in various applications. Ensure optimal performance by adding the alloy to aluminum liquid at temperatures ranging from 700 to 760°C. Achieve uniform dispersion by stirring evenly and allow the mixture to stand for 5 to 10 minutes before pouring.

- Dosage Guidelines:

- Add 0.8 to 1.5 kg per ton of pure aluminum

- Use 0.5 to 1 kg per ton for profiles and strips

- Add 1 to 2 kg for other aluminum alloys based on grain size requirements

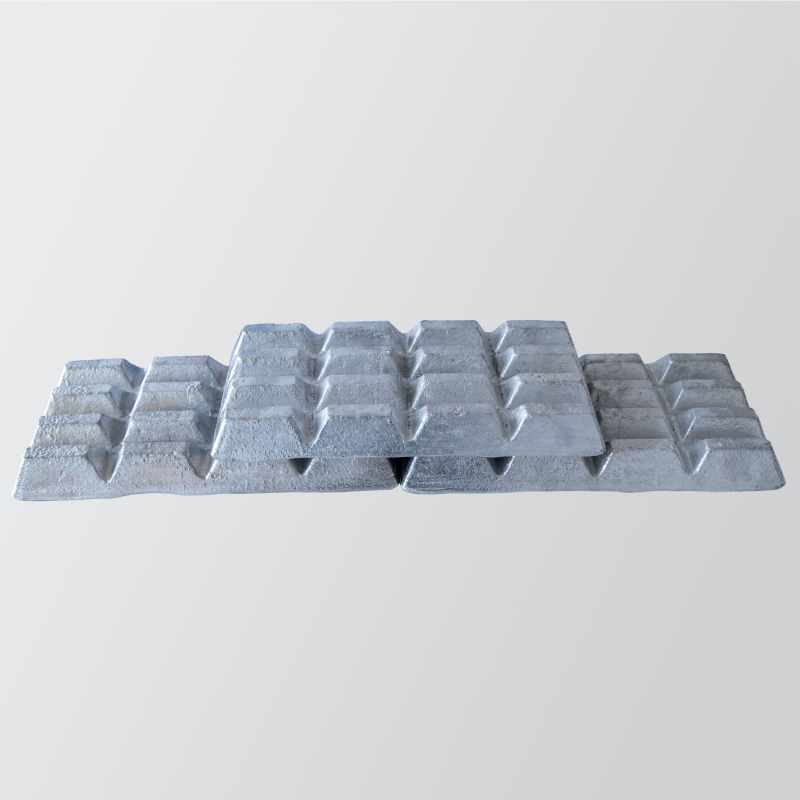

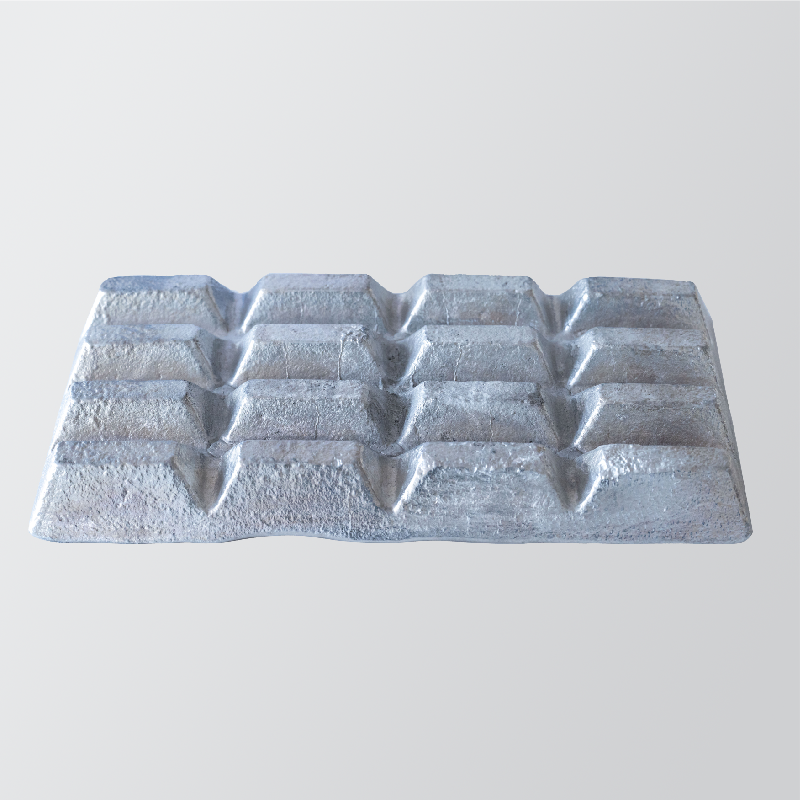

Packaging and Storage

- Packaging: Aluminum-Titanium-Boron alloys are available in screw rods and strips, distinguished by their metallic luster.

- Storage: Store the alloys in a ventilated, dry place. Ensure the area is moisture-proof to maintain quality.

Application Scenarios

Aerospace Field

Aluminum-Titanium-Boron alloys are essential in aerospace, used in manufacturing aircraft engines, brakes, and hydraulic systems. These applications leverage the alloy's high strength, stiffness, temperature resistance, and corrosion resistance.

Automobile Manufacturing Field

Widely adopted in automobile manufacturing, Aluminum-Titanium-Boron alloys contribute to constructing engines, transmissions, and body structures. The alloy's lightweight nature and high strength improve fuel efficiency and driving performance.

Industrial Machinery Field

In industrial machinery, these alloys are vital for machine tools, hydraulic machinery, and brakes. Their strength, stiffness, and fatigue resistance meet the high-performance material requirements.

Construction Engineering and Electrical & Electronic Fields

The alloy's high temperature resistance, hardness, and corrosion resistance make it ideal for construction and electrical applications, delivering outstanding performance and durability.

Preparation Method

Several methods exist for preparing Aluminum-Titanium-Boron alloys, including self-propagating high-temperature synthesis and aluminothermic reduction. The fluoride salt method is predominant, offering high yield, accessible raw materials, and cost-effective production.

Market Trend

The Aluminum-Titanium-Boron alloy market is expanding, driven by scientific advancements and diverse applications. Anticipate increased output and quality in the coming years, fueled by technological progress and rising demand.

Notable Properties

- High Hardness and Wear Resistance: Ideal for knives and wear-resistant parts.

- High Temperature and Non-Oxidation Resistance: Suitable for refractory parts in high-temperature ovens and aircraft engines.

- Corrosion Resistance: Perfect for corrosion-resistant materials like chemical aluminum and tungsten.