Al-Si Alloys for Casting & Auto Industry Use

Features of Our Aluminum Preliminary Alloy

- Constructed from homogeneous metal components

- Low smelting temperature for efficient processing

- Facilitates easy breakage and filling

- Contains high component contents ensuring easy absorption

Application and Usage

To achieve the desired control standards of elements within the flux, calculate the precise number of preliminary alloys needed. This ensures a harmonious blend with the flux. For composition adjustments, incorporate the preliminary alloy into the furnace charge, distributing it evenly across the intermediate layer.

Upon smelting, extract the flux and ensure uniform mixing. Proceed with a sample analysis to verify composition accuracy.

Packing and Storage Guidelines

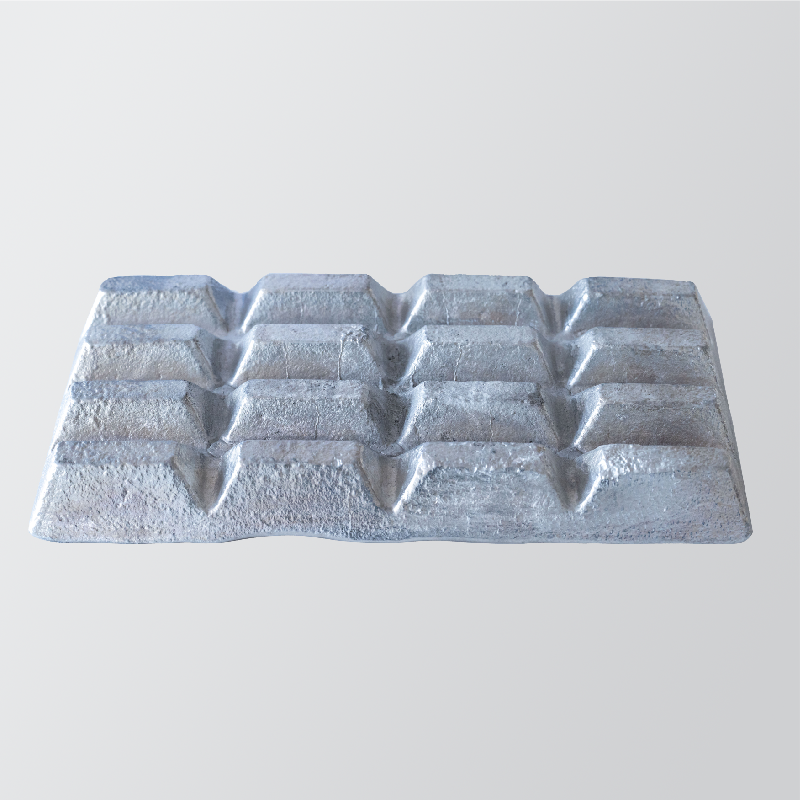

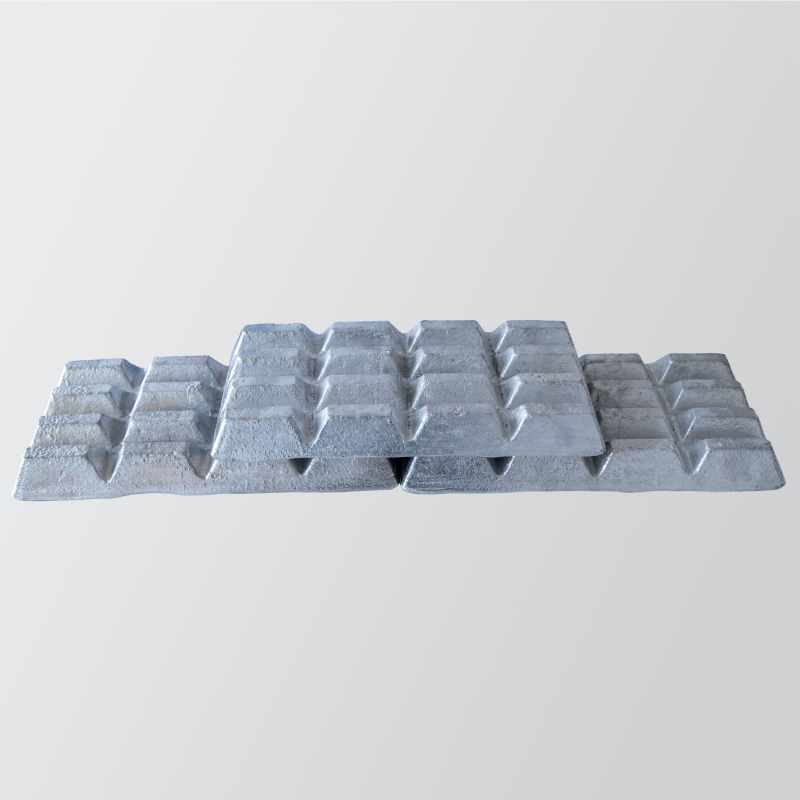

Our alloy ingots comply with national standard specifications. Each packet contains four alloy ingots, with an individual weight of approximately 25 kg (net weight). The label on the front of each ingot includes the alloy code, production date, and furnace number.

For optimal preservation, store the ingots in a dry warehouse. When sampling, select a piece of ingot and conduct an analysis at three mixed points along the diagonal of the smooth aluminum surface.

The Role of Aluminum Preliminary Alloy in Adjustment

Aluminum preliminary alloy serves as a traditional medium for refining aluminum melt compositions. Utilizing metallic elements with higher melting points, along with innovative melting methods, results in intermediates with significantly reduced smelting temperatures. This advancement enables the incorporation of high-temperature metallic elements into the aluminum liquid at lower temperatures, effectively adjusting the element contents of the aluminum melt.